what is forged flange ?

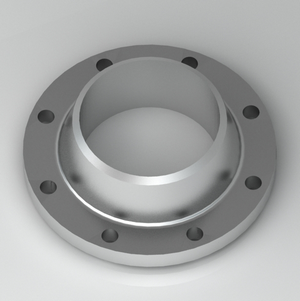

forged flange the conventional flange products. It is invented on the basis of the cast flange into production, its intensity to be higher than the cast steel flange many interconnected so that the tube with the tube parts, is connected to the tube end.

Hammered holes in the flange bolt flange abuts. Forged flange gasket sealing. Forged flange fittings (flanged pipe fittings) fittings with forged flange (flange or disk access). It can be cast from (Figure N), can also be threaded connections, or welding. Flanged connections (flange, joint) by a pair of flange, a gasket and a number of bolts and nuts. Gasket on the between two flange sealing surface, tighten the nut, than on the gasket surface deformation pressure reaches a certain value, and fill the sealing surface asperities join not leak tight.

Flange connection is a detachable connection. The coupled components can be divided into the vessel flange and pipe flange. Sub-structure type, integral flange, loose flanges and threaded flange. The common integral flange welded flange welded flange. less rigid forged flanges, applied to the pressure p �?4MPa occasions; welded neck flange, also known as high-neck flange, rigid, suitable for high temperature pressure.

forged flange sealing surface, there are three types: flat-type sealing surface, the high pressure is not applicable to, media nontoxic occasions; irregularities sealing surface, and applies a pressure slightly higher occasions; the sealing surface of the tongue and groove, applicable to flammable explosive, toxic media and high pressure occasions. The gasket is able to produce plastic deformation, and having a certain intensity of the material of the ring.