SORF Flange Dimensions- ASME ANSI B16.5 150lb/300lb/600lb

slip on flange with raised face (sorf flange), sorf flange dimension from 1/2 inch to 96 inch, pressure rating from 150lb/sq.in to 2500lb/sq.in, we usually offer ANSI/ASME/DIN etc. Standard Flange with sorf flange dimension.

- 150lb Slip On Flange with raised face from 1/2 inch to 24 inch of B16.5

- 300lb Slip On Flange with raised face from 1/2 inch to 24 inch of B16.5

- 600lb Slip On Flange with raised face from 1/2 inch to 24 inch of B16.5

- 900lb Slip On Flange with raised face from 1/2 inch to 24 inch of B16.5

- 1500lb Slip On Flange with raised face from 1/2 inch to 24 inch of B16.5

- 2500lb Slip On Flange with raised face from 1/2 inch to 24 inch of B16.5

ASME/ANSI B16.5 150lb Slip on Flange/Standards, Dimensions & Weight

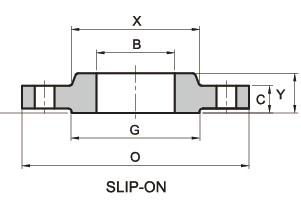

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub |

Diameter of Raised Face | Length Hub.Y | Bore | Diam. of Bolt Circle |

Diam. of Bolt Holes |

Number of Bolts |

Diam. of Bolts (inch) |

KG | LB | |

| inch | dn | O | C | X | G | Y | B | BC | BH | BN | BD | ||

| 1/2" | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 15.70 | 22.40 | 60.50 | 15.80 | 4 | 1/2" | 0.4 | 0.9 |

| 3/4" | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 15.70 | 27.70 | 69.90 | 15.80 | 4 | 1/2" | 0.7 | 1.5 |

| 1" | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 17.50 | 34.50 | 79.30 | 15.80 | 4 | 1/2" | 0.8 | 1.8 |

| 1-1/4" | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 20.60 | 43.20 | 88.90 | 15.80 | 4 | 1/2" | 1.2 | 2.6 |

| 1-1/2" | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 22.40 | 49.50 | 98.60 | 15.80 | 4 | 1/2" | 1.4 | 3.1 |

| 2" | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 25.40 | 62.00 | 120.70 | 19.10 | 4 | 5/8" | 2.2 | 4.8 |

| 2-1/2" | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 28.40 | 74.70 | 139.70 | 19.10 | 4 | 5/8" | 3.5 | 7.7 |

| 3" | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 30.20 | 90.70 | 152.40 | 19.10 | 4 | 5/8" | 3.8 | 8.4 |

| 3-1/2" | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 31.80 | 103.40 | 177.80 | 19.10 | 8 | 5/8" | 5 | 11 |

| 4" | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 33.30 | 116.10 | 190.50 | 19.10 | 8 | 5/8" | 5.6 | 12.3 |

| 5" | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 36.60 | 143.80 | 215.90 | 22.40 | 8 | 3/4" | 6.5 | 14.3 |

| 6" | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 39.60 | 170.70 | 241.30 | 22.40 | 8 | 3/4" | 8.1 | 18 |

| 8" | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 44.50 | 221.50 | 298.50 | 22.40 | 8 | 3/4" | 13 | 28.6 |

| 10" | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 49.30 | 276.40 | 362.00 | 25.40 | 12 | 7/8" | 18.4 | 40 |

| 12" | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 55.60 | 327.20 | 431.80 | 25.40 | 12 | 7/8" | 28.5 | 63 |

| 14" | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 57.20 | 359.20 | 476.30 | 28.50 | 12 | 1" | 37.5 | 83 |

| 16" | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 63.50 | 410.50 | 539.80 | 28.50 | 16 | 1" | 44.5 | 98 |

| 18" | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 68.30 | 461.80 | 577.90 | 31.80 | 16 | 1 1/8" | 54 | 119 |

| 20" | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 73.20 | 513.10 | 635.00 | 31.80 | 20 | 1 1/8" | 72 | 158 |

| 24" | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 82.60 | 616.00 | 749.30 | 35.10 | 20 | 1 1/4" | 95 | 209 |

NOTE: 1. Class 150 flanges except Lap Joint will be furnished with 0.06 (1.6mm) raised face, which is included in ‘Thickness�?(C) and ‘Length through Hub�?(Y1), (Y3). 2. For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees. 3. Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub. 4. The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (C). 5. Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option.

ASME/ANSI B16.5 300lb Slip on Flange/Standards, Dimensions & Weight

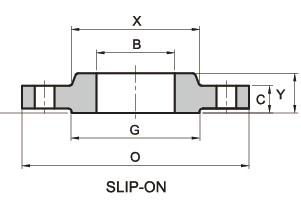

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub |

Diameter of Raised Face | Length Hub.Y | Bore | Diam. of Bolt Circle |

Diam. of Bolt Holes |

Number of Bolts |

Diam. of Bolts (inch) |

Approx. Weight | ||

| inch | dn | O | C | X | G | Y | B | BC | BH | BN | BD | KG/PCS | LB/PCS |

| 1/2" | 15 | 95.5 | 14.2 | 38.1 | 35.1 | 22.4 | 22.4 | 66.5 | 15.7 | 4 | 1/2" | 0.7 | 1.5 |

| 3/4" | 20 | 117. 5 | 15.7 | 47.8 | 42.9 | 25.4 | 27.7 | 82.6 | 19.1 | 4 | 5/8" | 1.2 | 2.6 |

| 1" | 25 | 124. 0 | 17.5 | 53.8 | 50.8 | 26.9 | 34.5 | 88.9 | 19.1 | 4 | 5/8" | 1.4 | 3.1 |

| 1-1/4" | 32 | 133. 5 | 19.1 | 63.5 | 63.5 | 26.9 | 43.2 | 98.6 | 19.1 | 4 | 5/8" | 1.8 | 4 |

| 1-1/2" | 40 | 155. 5 | 20.6 | 69.9 | 73.2 | 30.2 | 49.5 | 114.3 | 22.4 | 4 | 5/8" | 2.7 | 6 |

| 2" | 50 | 165. 0 | 22.4 | 84.1 | 91.9 | 33.3 | 62 | 127 | 19.1 | 8 | 5/8" | 3.2 | 7 |

| 2-1/2" | 65 | 190. 5 | 25.4 | 100.1 | 104.6 | 38.1 | 74.7 | 149.4 | 22.4 | 8 | 3/4" | 4.5 | 9.9 |

| 3" | 80 | 209. 5 | 28.4 | 117.3 | 127 | 42.9 | 90.7 | 168.1 | 22.4 | 8 | 3/4" | 5.9 | 13 |

| 3-1/2" | 90 | 228. 5 | 30.2 | 133.4 | 139.7 | 44.5 | 103. 4 | 184.2 | 22.4 | 8 | 3/4" | 7.5 | 16.5 |

| 4" | 100 | 254. 0 | 31.8 | 146.1 | 157.2 | 47.8 | 116. 1 | 200.2 | 22.4 | 8 | 3/4" | 10 | 22 |

| 5" | 125 | 279. 5 | 35.1 | 177.8 | 185.7 | 50.8 | 143. 8 | 235 | 22.4 | 8 | 3/4" | 12.5 | 27.5 |

| 6" | 150 | 317. 5 | 36.6 | 206.2 | 215.9 | 52.3 | 170. 7 | 269.7 | 22.4 | 12 | 3/4" | 16.5 | 36.4 |

| 8" | 200 | 381. 0 | 41.1 | 260.4 | 269.7 | 62 | 221. 5 | 330.2 | 25.4 | 12 | 7/8" | 25.5 | 56 |

| 10" | 250 | 444. 5 | 47.8 | 320.5 | 323.9 | 66.5 | 276. 4 | 387.4 | 28.4 | 16 | 1" | 35 | 77 |

| 12" | 300 | 520. 5 | 50.8 | 374.7 | 381 | 73.2 | 327. 2 | 450.9 | 31.8 | 16 | 1 1/8" | 52 | 115 |

| 14" | 350 | 584. 0 | 53.8 | 425.5 | 412.8 | 76.2 | 359. 2 | 514..4 | 31.8 | 20 | 1 1/8" | 73 | 161 |

| 16" | 400 | 647. 5 | 57.2 | 482.6 | 469.9 | 82.6 | 410. 5 | 571.5 | 35.1 | 20 | 1 1/4" | 88 | 194 |

| 18" | 450 | 711. 0 | 60.5 | 533.4 | 533.4 | 88.9 | 461. 8 | 628.7 | 35.1 | 24 | 1 1/4" | 115 | 253 |

| 20" | 500 | 774. 5 | 63.5 | 587.2 | 584.2 | 95.3 | 513. 1 | 685.8 | 35.1 | 24 | 1 1/4" | 139 | 306 |

| 24" | 600 | 914. 5 | 69.9 | 701.5 | 692.2 | 106. 4 | 616. 0 | 812.8 | 41.1 | 24 | 1 1/2" | 212 | 467 |

NOTE: 1. Class 600 flanges except Lap Joint will be furnished with 0.25 (6.35mm) raised face, which is not included in ‘Thickness�?(C) and ‘Length through Hub�?(Y1), (Y3). 2. For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees. 3. Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub. 4. The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (C). 5. Dimensions of sizes 1/2 through 3 1/2 are the same as for Class 400 Flanges. 6. Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option.